| |

|

|

| |

Calorized Pipe |

|

| |

|

|

|

| |

|

|

| |

|

|

| |

|

|

| Calorised Steel Pipe is continuously hot dip diffusion coated inner & outer with an aluminum coating according to the standard of GB/T18592-2001.The hot dip diffusion process, pioneered by Xingrui, provides a tight metallurgical bond between the steel and the coating,lance pipe lasts five to seven times longer than mid steel pipe in oxygen injection,also shorten the tap-time in the oxygen enrichment operation |

| In our calorising process, the diffusion layer formed is a mixture of iron and aluminides, dependent on the substrate material, with an aluminium content of between 30 and 45 wt. % at the surface. The percentage of aluminium gradually decreases through the diffusion zone to that of the substrate material. |

| This process results in a material with the strength of steel plus the corrosion protection of aluminum, and the synergistic heat protection of an aluminum alloy,high temperature resistance can reach to 600℃。 |

| In any calorising process, components are placed in a steel retort surrounded by a powder mixture containing aluminium, a halide and an inert diluent. The retort is then sealed, placed into a furnace and heated to an elevated temperature, held at temperature and then slowly cooled back to room temperature. After cooling the components are removed from the retorts and cleaned to remove any compound or residues. |

| In the process of steel manufacturing by open hearth or electric furnace, the consumption rate of lance pipes for oxygen injection sows rather high ratio owing to high temperature and severe oxidation. In general, steel pipes are used as lance pipes for oxygen injection. If mild steel pipes are treated by this process consumption rate of lance pipes will increase 6 - 7 times. It is necessary to make the pipe fireproof as a first step. Special treatment is then needed to protect the pipe from any falling-off or scaling-off by shock or by bending stress. |

| As a result of research conducted over many years, it was discovered that the most effectual method is to diffuse aluminium into the pipe's surface, so as to promote wear proof properties on steel pipe. That is to say, calorising is to be carried at, in and outside of the steel pipe to promote wear and fire proof properties of the pipe. |

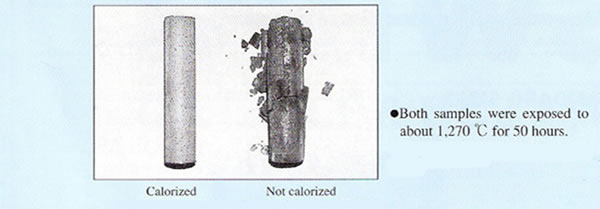

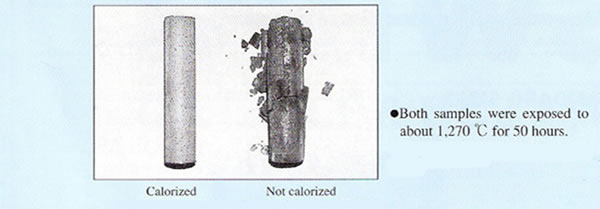

| Comparison with Mild Steel |

|

| |

| Principle of Calorized Lance |

| When calorized lance is exposed to high temperature, the calorized layer forms a heat resistant aluminum oxide ( alumina ) film over the surface and protects mild steel against severe oxidation. |

|

| |

| |

| |